Below are the benefits of dewatering technology with SoilTain® geosynthetic tubes: Below are the benefits of dewatering technology with SoilTain® geosynthetic tubes:

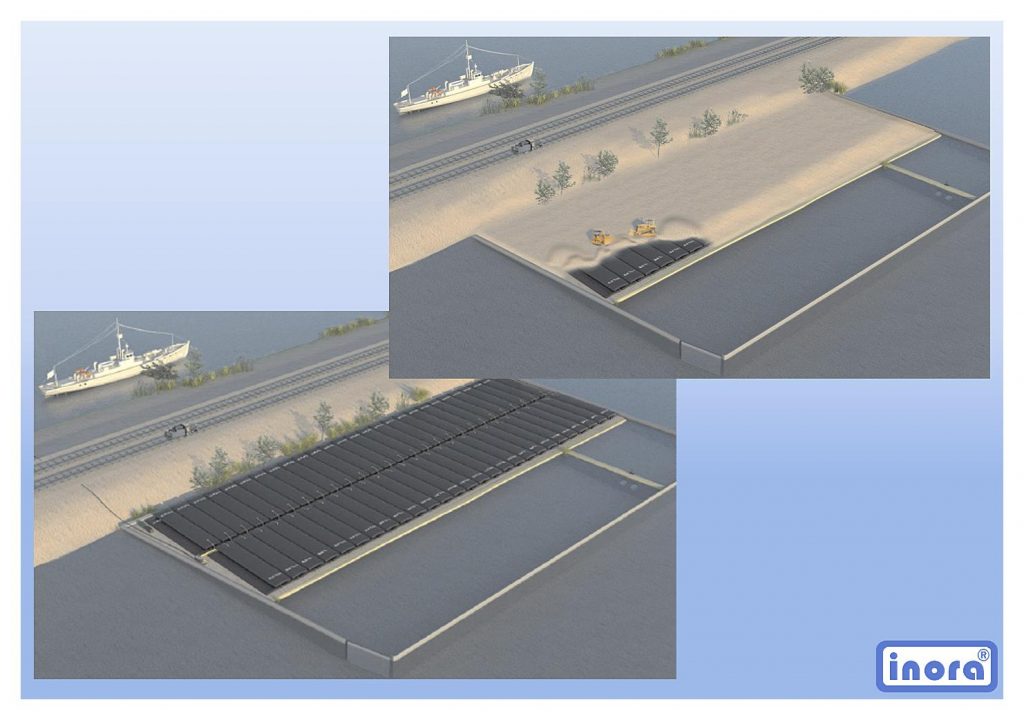

- geosynthetic tubes with custom sizes – SoilTain® dewatering tubes are installed on a properly prepared silting field, and their size is adjusted to available space, so the interference in the environment is as small as possible;

- reduction of required land – geosynthetic containers can be placed in several layers, what reduces the required area;

- protection against rewetting – pumping of the sludge during the dewatering process is not affected by heavy rains, because external atmospheric precipitation flows down the surface of the synthetic sleeve without getting inside. If dewatering is carried out in presses, bagging machines or centrifuges, the sludge must be immediately disposed in order to avoid ist rewetting.

- minimal use of heavy equipment – compared with the traditional method of sludge extraction where water is drained from a reservoir, the amount of heavy equipment used is significantly reduced. In the technology of SoilTain® dewatering tubes, only the dredger works on the water reservoir. On the other hand, the extraction of sediment from a dry reservoir involves the use of a number of excavators, bulldozers, loaders, etc., which is also associated with significant environmental degradation;

- minimization of odor intensity – an additional advantage, which should be mentioned here, is the fact that the pumped sediments are transferred via a pipeline directly to geosynthetic tubes where they are dewatered. Therefore, they are not in a direct contact with the atmosphere, which means a significant reduction of pollutants concentration in the air (if any), and hence, it minimizes the intensivity of an unpleasant smell. In the case of realization with presses, bagging machines or centrifuges, the dewatered sludge is successively stored until it is removed, which is associated with the formation of odors.

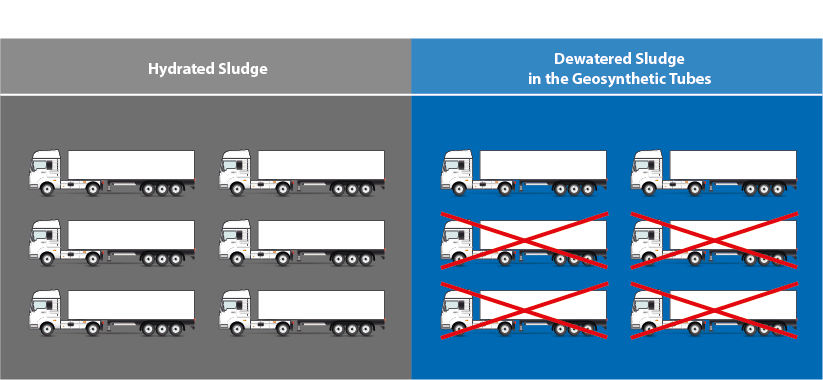

- lower costs of transport and disposal – one of the reasons for the growing popularity of this method is the economic aspect – as a finished product a dried sludge is obtained, which significantly affects their volume, and thus the costs of transport and disposal. For sludge dewatered with this method, it is not necessary to use tub-type trucks.

- possibility of sludge management on site – if the sediments from the water reservoir do not pose a threat to the environment, do not contain toxic substances,

and the parameters do not exceed the prescribed standards, it is also possible to bury geosynthetic tubes at their initial location after the process is completed. The area can be greened or used for other purposes;

- lack of deposited sediments in the lagoons – another advantage of the solution offered by our company, is no need to create sedimentary lagoons. The deposited sediments must be removed after a certain period of time or during the liquidation of the lagoons. The use of geosynthetic tubes enables immediate dewatering of highly hydrated sludge, and thus ist significant reduction, what allows the ongoing management of the material;

- low demand for electricity – using geocontainers the sludge is dewatered to the same level as in presses, bagging machines or centrifuges. Dewatering is done by gravity, without electricity – not including pumps that operate the process. Therefore, the operating costs are disproportionately lower compared with the mechanical methods. The SoilTain® technology does not require purchasing of machines that require regular service and sometimes break down.

- preserved functionality of the reservoir – due to retaining water in the reservoir at the current level through the duration of the project, the functionality of the reservoir is maintained, ie flood protection, recreational – tourist, water intake for the needs of the heat and power plants, fishing;

- low interference in the environment – the influence on the water ecosystem is inconsiderable, the reservoir is not getting empty during the process, what allows the fauna and flora of the reservoir to be kept in the best possible condition.

Environment and technology of SoilTain® geosynthetic tubes

Read more about the positive environmental impact of SoilTain® technology