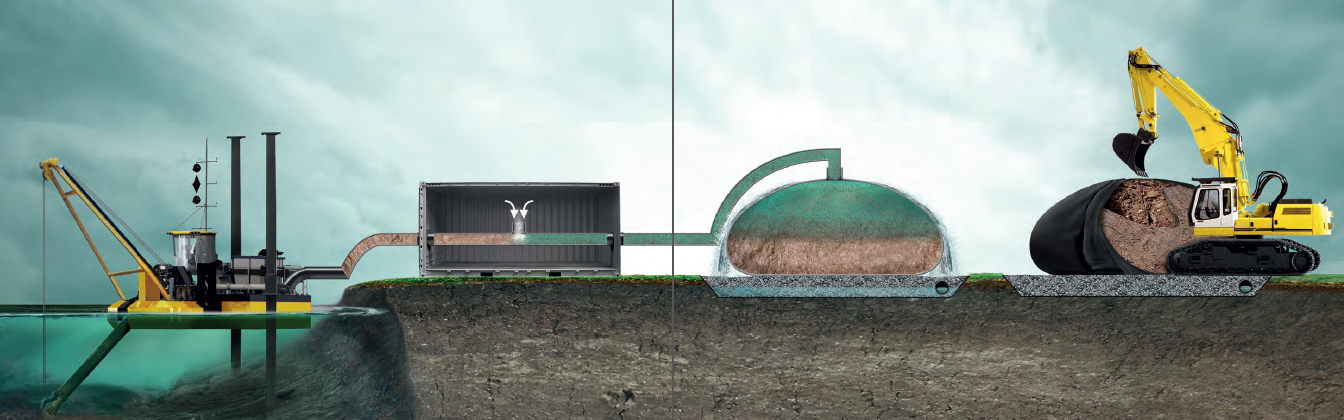

The technology we offer, provides an effective dewatering of all kinds of sludge by means of the Huesker SoilTain® geosynthetic tubes (Fig. 1) This method works well for dewatering of sewage sludges through bottom sediments of water reservoirs, marine sediments or various types of post-production sludges.

The technology consists on collection of hydrated sludge by a pump appropriate for a given implementation, and then directing the dredged materials through the flocculation process to synthetic containers where dewatering takes place. After the dewatering process is completed, the sludge can be removed from the container coat.

Fig. 1 Technology of dewatering in SoilTain® geosynthetic tubes

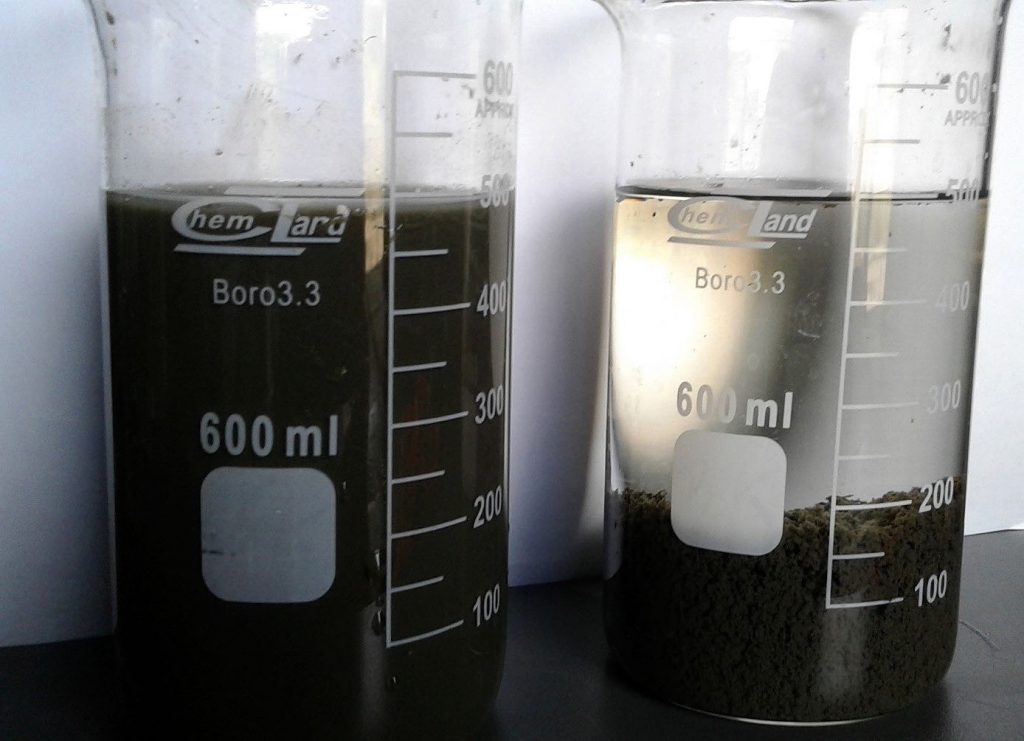

A very important element of the sludge dewatering technology in SoilTain® geosynthetic tubes is the dosing of the polyelectrolytes (flocculants) to hydrated sludge.

The application of polyelectrolytes allows to easily dispose excess water from the sediment. The use of this type of sludge aggregating substance (flocculation process) is necessary for proper and effective sludge dewatering.

Photo 1 shows two sludge samples (picture on the left: unconditioned sludge), (picture on the right: sample after the flocculation process, i.e. after polyelectrolyte have been added.

Due to the wide application of polyelectrolytes during activities carried out in various water bodies and considering influence on the natural environment, a number of ecotoxicological tests have been carried out on these substances. The use of polyelectrolytes is legally regulated by Ordinance EU 1272/2008, where flocculants are classified as non-hazardous for human health and the environment, and Directive 1999/45/EC, which does not classify polyelectrolytes as hazardous. Each of the conditioning substances has a Data Sheet, which contains information on extensive ecotoxicological studies on individual living organisms, confirming the lack of toxicity of the substance.

The polyelectrolyte solution is dosed into the output automatically by a dosing pump depending on the flow parameters and the dry matter (weight) content of the sludge. Control and measurement equipment ensures full automation of the entire process, and thus the dosing pump exactly doses polyelectrolyte that is required. As a result, the polyelectrolyte binds with sludge particles, that do not get into the water, and are drained away from the geosynthetic container.

Not for nothing, on the market there is a great variety and choice of polyelectrolytes available. Each sediment is different. Therefore, in the process of accelerated sedimentation, one of the most important activity is to properly select the aggregating substance and type of the SoilTain® geosynthetic tube before a given project starts. It is necessary to properly match those elements that guarantee effective, quick and economic sludge dewatering.

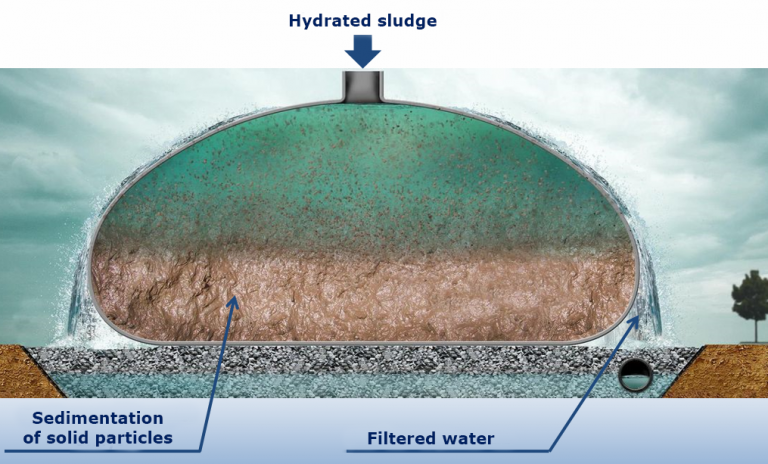

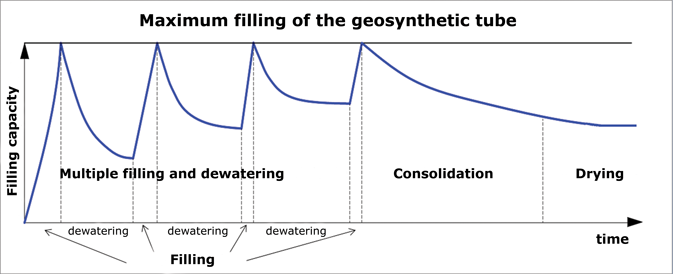

The target dewatering process begins with filling the container with conditioned sludge through the available inlet funnels. The geosynthetic sleeve is filled to the previously estimated maximal height, then it will be waited for the volume reduction Fig. 2. The geosynthetic container is filled several times with consecutive batches of conditioned sludge until the maximal volume level is reached. In the last stage, the final material consolidation process and its final drying take place. The consecutive stages of the process are presented in Figure 3.

The SoilTain® tubes are made of special geosynthetic products, most often polyester or polypropylene geotextiles. Specially sewn textiles form a synthetic sleeve that has inlet chimneys to deliver the hydrated sludge. The container itself is up to 65 meters long and has a capacity of even about 1500 m3 (dewatered sludge!). Depending on the realization or the terrain topography, they are arranged either next to or on each other. Due to the proper selection of material technical parameters (like pore size, strength, etc.), the geosynthetic tube allows an effective water dewatering while at the same time keeping the sediment material inside the structure.

Upon completion, the sludge is dewatered in geosynthetic containers, what is resulting in a significant sludge volume reduction. The dry sludge is most often extracted by cutting open a synthetic sleeve. It is then transported to its final storage or utilization site. The dewatered sludge may also remain in the containers on an appropriately prepared and profiled area and backfilled at the final stage.

Benefits of SoilTain® technology

Read more about the benefits and advantages of this technology